PVD & ALD Coatings to make a surface resist wear, friction, harsh chemicals, or heat

Coatings We Specialize In:

PVD COATINGS

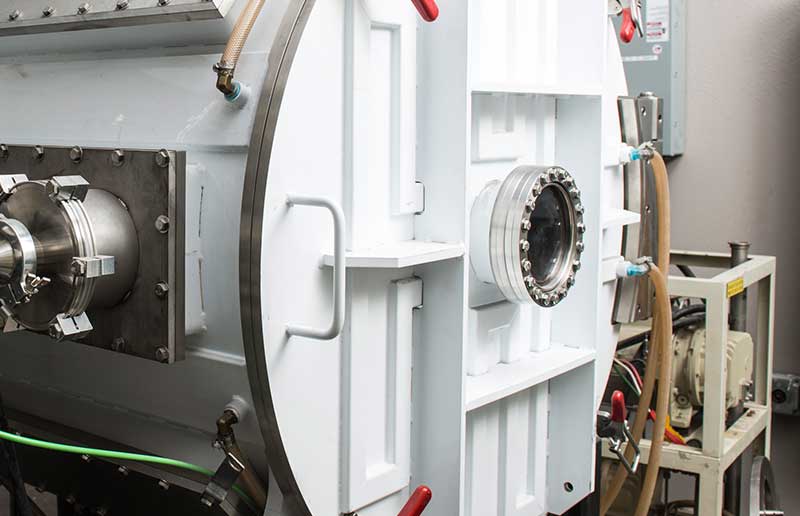

PVD Coatings (Physical Vapor Deposition) is a vacuum method that can apply various films at varying temperatures. PVD Coating is known for its flexibility and versatility.

SPUTTERING

Sputtering is a form of PVD which uses ionized gas to ablate (“sputter”) a target to create a thin film of that material on a substrate.

CATHODIC ARC

Cathodic arc is another type of (PVD) Physical Vapor Deposition known for coating adhesion, uniformity, utility on parts with 3-dimensional structure and scalability.

ALD COATINGS

ALD Coatings (Atomic Layer Deposition) is a vapor phase technique capable of producing thin films of a variety of materials. It is ideal for odd shaped items.

Injection Molds

Increase the life expectancy of your molds and fix leaking cooling channels with PVD coating.

Additive Manufacturing

Transform the capabilities of your 3D printed products using thin-film deposition.

Harsh Environments

Have a part that needs to withstand heat, friction, or harsh chemicals? PVD coatings can help.

Tool Coatings

Protective coatings for everything from the operating table to the oil field.

Testimonials

Doug Collins | Avid Product Development

Jeff Simpson | West Coast Quartz