Game-Changing: Surface Coatings For Injection Molds

We see some interesting things with the injection molds that come across our plate. From parts sticking to galling, there are a lot of issues that can kill mold performance. The good news, surface coatings for injection molds can solve many of these issues. Let’s take a look at common Issues we use surface coatings

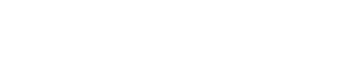

How To Clean Injection Molds

Does cleaning an injection mold benefit performance? How do you clean an injection mold? And can you cause damage by cleaning too much? All great questions that we’ll answer here. For a little expert insight, I sat down with Steve Johnson, President and Founder of MoldTrax, to talk about tips and advice on mold cleaning.

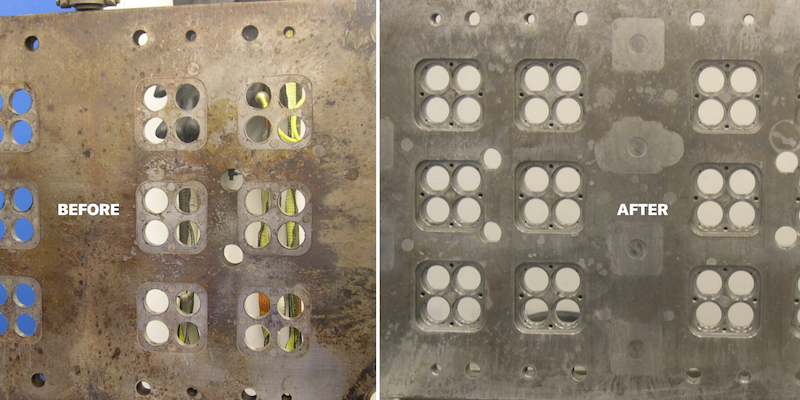

Can PVD coating transform what’s possible with 3D printing?

We’re always testing the boundaries of what’s possible with surface modification. From Injection Molds to semiconductors, we coat products subjected to a range of harsh conditions. One area that presents a wealth of opportunity—where we’re extensively testing and a little bit obsessed—is 3D printing. Surface modification is proving to be a game-changer for products in need

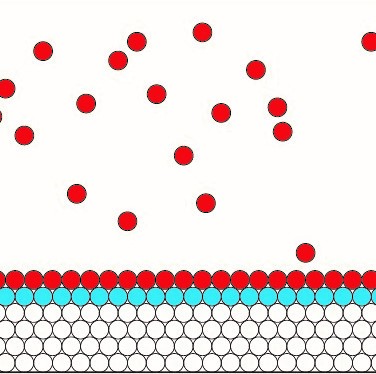

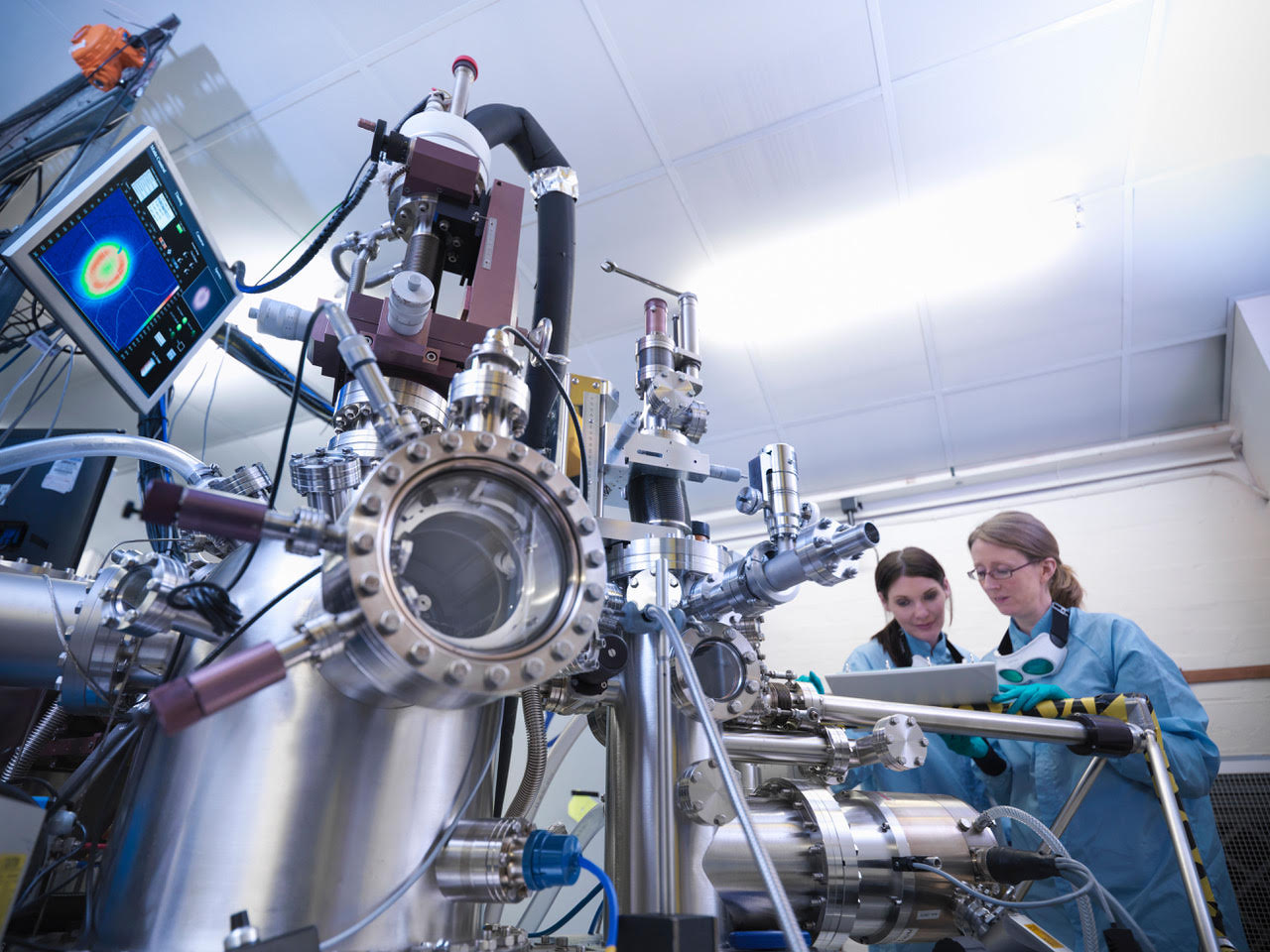

An Introduction to Vacuum Coating

Vacuum coatings are used to protect everything from medical tools to aerospace parts. They help objects resist wear, friction, harsh chemicals, and heat so they’ll last longer. Unlike other protective coatings, thin-film deposition (vacuum) coatings don’t bring unwanted side-effects – Other coating techniques run the risk of knocking a tool out of tolerance or adding

Electroplating vs. Physical Vapor Deposition

For many injection mold companies, electroplating is the way coatings have always been done. Companies in the U.S. have worked since the 1800s to hone electroplating processes and today it’s one of the most popular injection mold coatings available. It increases abrasion resistance and has high hardness when done right. However, you may be missing

DLC Coating vs PVD Coating For Injection Molds

Sizing up two heavyweights in the coating world. The right injection mold coating can save a company hundreds of thousands of dollars. It makes an injection mold more corrosion-proof, durable, and assists in part release. That’s important, because it’s essential that a mold both last and maintain efficiency once coated. Knowing this begs the question:

Surface Coating For Better Mold Release

Don’t you hate it when you spend hundreds of thousands of dollars on mold design and fabrication, you think through every possible issue and then a part still gets hung up in the tool? We understand. It’s these issues that keep our technical team working late to improve mold coatings. Release coatings are necessary to

Using Atomic Layer Deposition to Protect Complex Geometries

The layered detail of ALD… Atomic Layer Deposition (“ALD”), a method of thin film deposition, has become popular due to its ability to create a durable surface with high levels of control over thickness, composition, and conformality. Although the method has been around for decades, the more recent need to coat increasingly complex 3D surfaces

How to Buy a PVD Coating, part 3

This is part 3 of a 3-part series Part 3: How to Buy a PVD Coating with No Fuss This is Part 3 of Alcadyne’s guide on how to make buying a PVD coating easier. Read Part 2 here and Part 1 here. In part 1 I discussed how buying a PVD coating is different

How to Buy a PVD Coating, part 2

This is part 2 of a 3 part series Part 2: Making a PVD Coating is Like Painting a House This is part 2 of Alcadyne’s guide on how to make buying a PVD coating easy. Read Part 1 here. In part 1 of How to Buy a PVD Coating I covered the ins and