Part 3: How to Buy a PVD Coating with No Fuss

This is Part 3 of Alcadyne’s guide on how to make buying a PVD coating easier. Read Part 2 here and Part 1 here.

In part 1 I discussed how buying a PVD coating is different than buying a part manufactured from scratch from a machine shop –

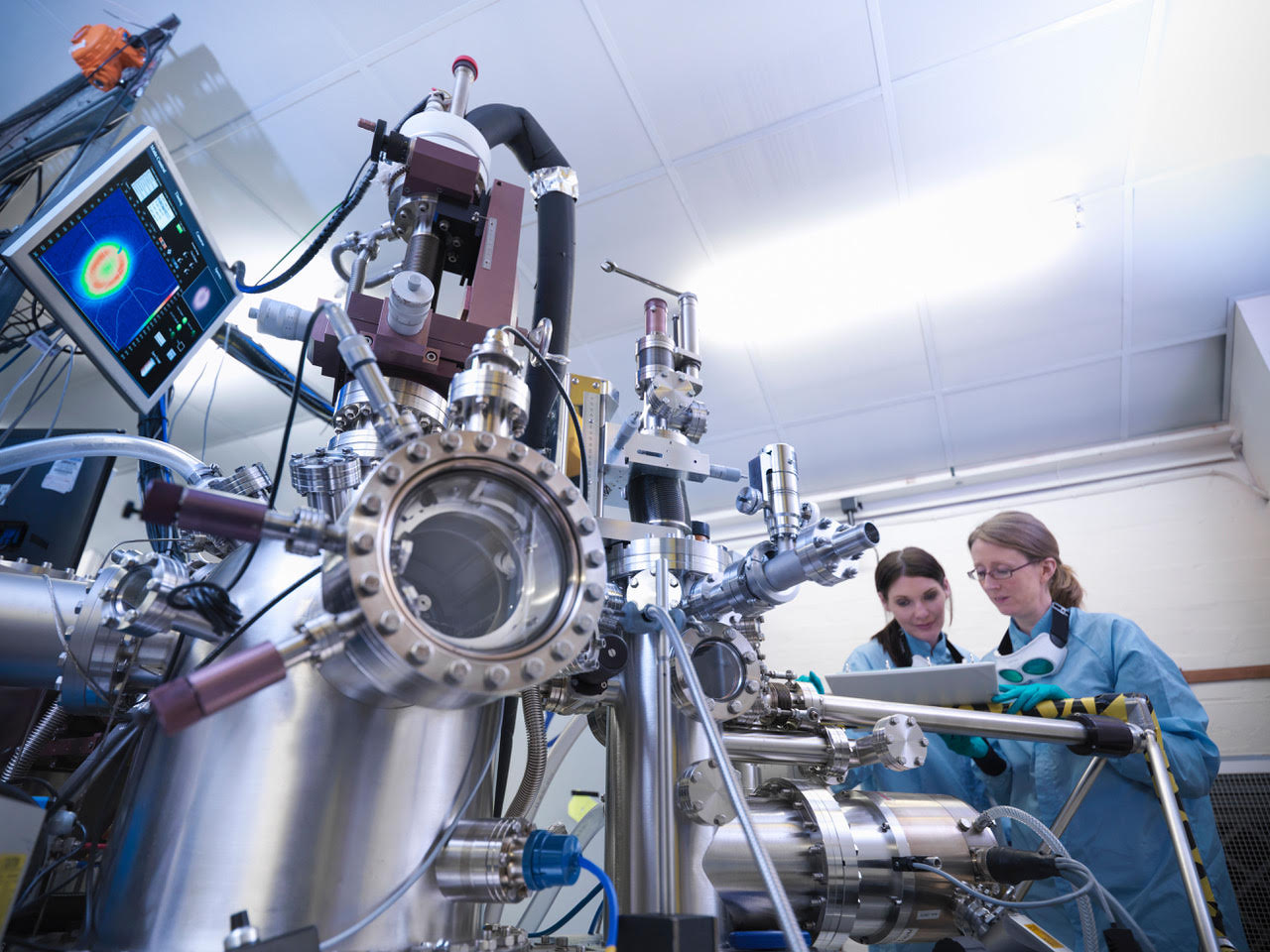

PVD coatings are placed on top of a substrate, and as a result the PVD coating process is best thought of as part of an integrated solution. Because PVD coating companies are impacted by what happens to your part before they receive it and after they send it back to you, we need a lot of information to get you what you need.

In part 2 I used the analogy that a PVD coating service is much like that of having the rooms of your house painted –

There’s a specific end goal, but the keys to success are often in the preparation work.

Now that you understand why buying a PVD coating involves sharing so much information just to get a quote, let’s talk about how you can use this to your advantage to buy exactly the coating you need with a minimum of hassle.

The key is to have your information organized. Once you narrow down to a small handful of companies that you would like to have detailed quotations from,

Have the following information on hand:

What is your part made of and how do you know?

- It is important to be specific.

- While Alcadyne has the metrology equipment for research and development to identify alloys and plastics, it’s best to hear this from the customer –

- Knowing that it is aluminum is better than just being able to say that it is metal, but it would be best to tell us, for example, that it’s Aluminum 5032.

What are all the steps in the existing manufacturing process?

- Based on your workflow and product requirements, consider where the coating might fit best.

- Disclose more steps than you think you need to. Without the kind of specific expertise Alcadyne has, it can be difficult to know what steps will negatively impact the surface quality.

The kinds of manufacturing steps we always need to know about are machining (especially for plastics), cutting fluids, cleaning steps, heat treatments, pickling, chemical strengthening, painting, sanding, blasting, shipping (packaging material), and quality control tests.

What are the conditions in which the final part is used?

- Consider the temperature, the environment, other materials or chemicals which will be present, and expected service life.

What’s the definition of success?

- What specific performance metrics are you going to measure to evaluate the coating?

- What performance, dimensional or quality tests will the coated part need to pass?

How many pieces will you need to test under certain conditions to gain confidence in the fitness of the coating supplied?

- Will you be able to supply brand new pieces for coating?

- New parts are preferred to avoid having to deal with the unknown history of a part.

Are there material constraints?

- Are there elements or classes of materials which can’t be used in your application?

- Consider the origin of your existing material constraints – would it be okay if an otherwise unacceptable material was encapsulated by a coating?

With this information in hand, you’ll be ready for the detailed questions that a PVD coating manufacturer might have in order to be able to provide you with a working solution that meets your needs.

If you have an idea what you want, it’s not a bad idea to do some homework about what types of coatings might be suitable for your application. This is helpful to us because it helps us understand your application and what’s important to you. It can also skip some trial and error, especially if you know for sure what will work for your application.

But leave room for creativity of the PVD coater

Allow us to leverage our experience with a variety of applications to develop new solutions to your problems.

You’re more likely to get creative solutions if you describe the challenge you’re trying to solve than if you ask for a specific coating and thickness.

I hope this series on How to Buy a PVD Coating has been helpful. Please Contact Us, if you would like more detail, have questions on how physical vapor deposition works, or just want to know how creative we can be.