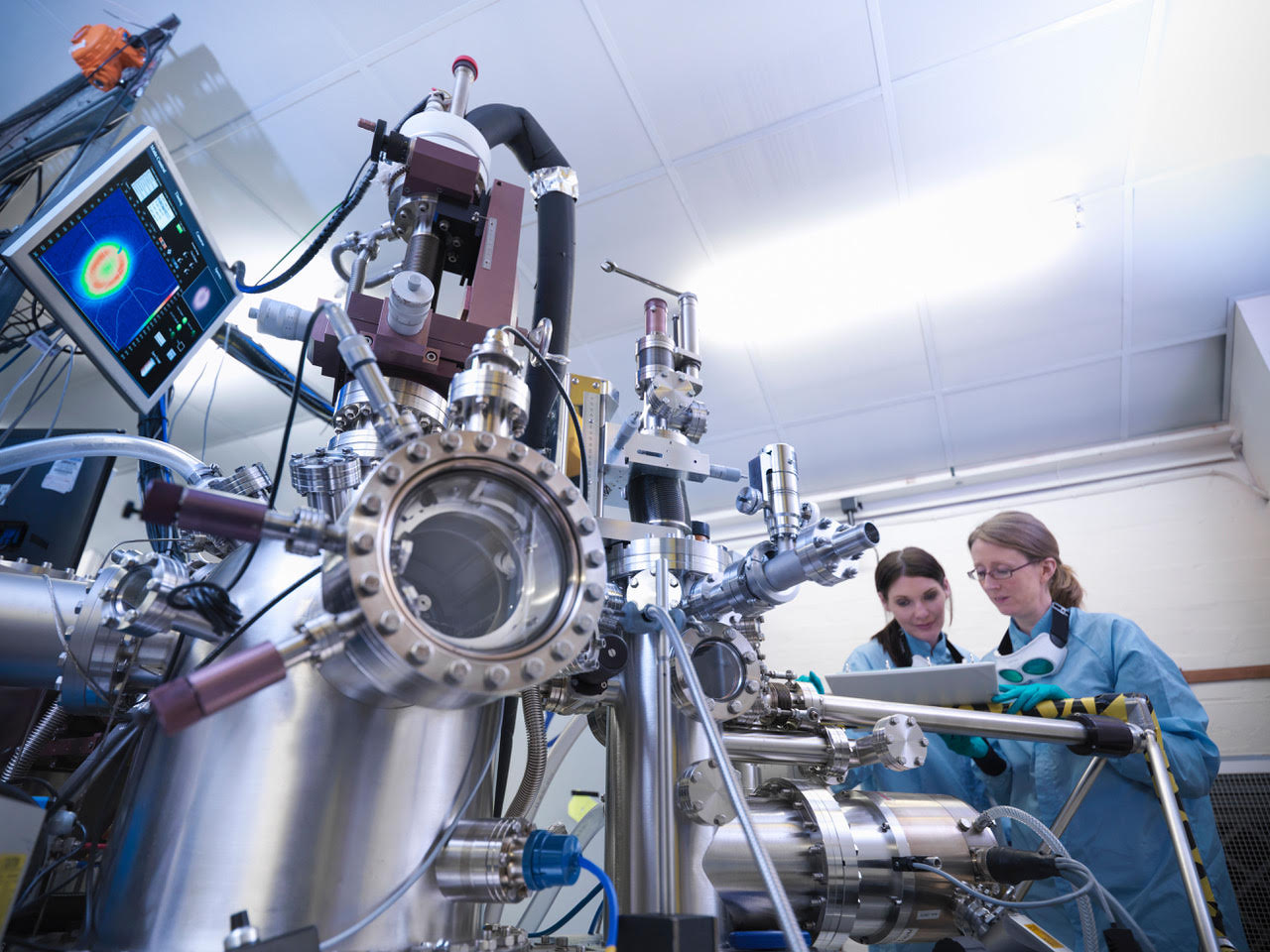

Electroplating vs. Physical Vapor Deposition

For many injection mold companies, electroplating is the way coatings have always been done. Companies in the U.S. have worked since the 1800s to hone electroplating processes and today it’s one of the most popular injection mold coatings available. It increases abrasion resistance and has high hardness when done right. However, you may be missing …