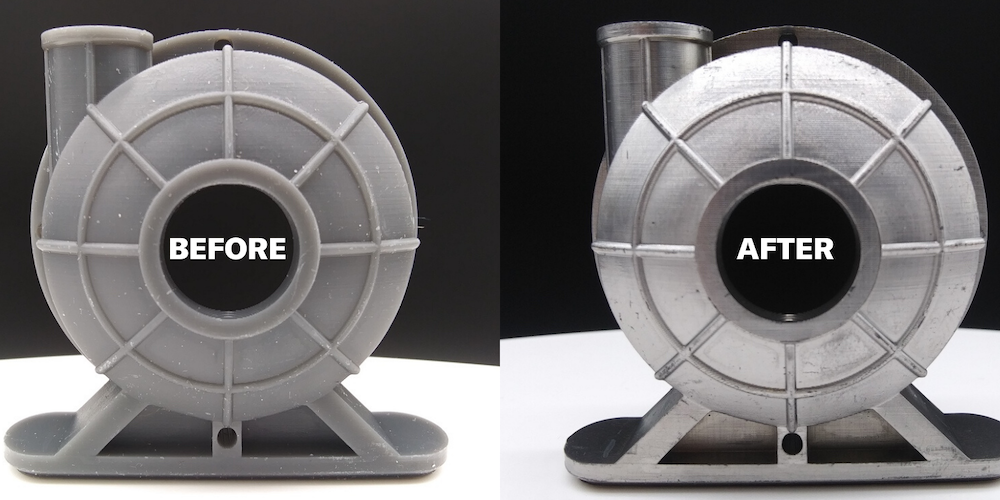

Can PVD coating transform what’s possible with 3D printing?

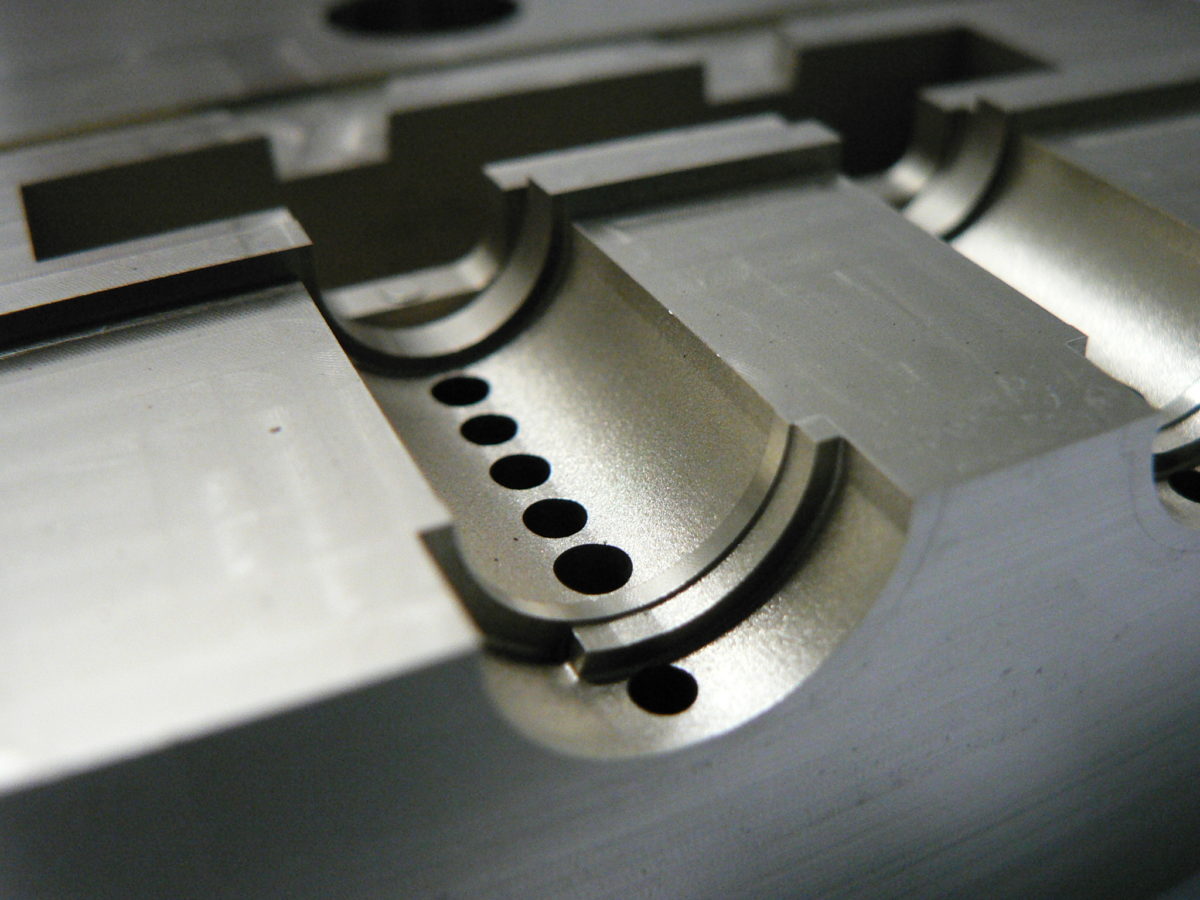

We’re always testing the boundaries of what’s possible with surface modification. From Injection Molds to semiconductors, we coat products subjected to a range of harsh conditions. One area that presents a wealth of opportunity—where we’re extensively testing and a little bit obsessed—is 3D printing. Surface modification is proving to be a game-changer for products in need …