Game-Changing: Surface Coatings For Injection Molds

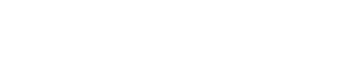

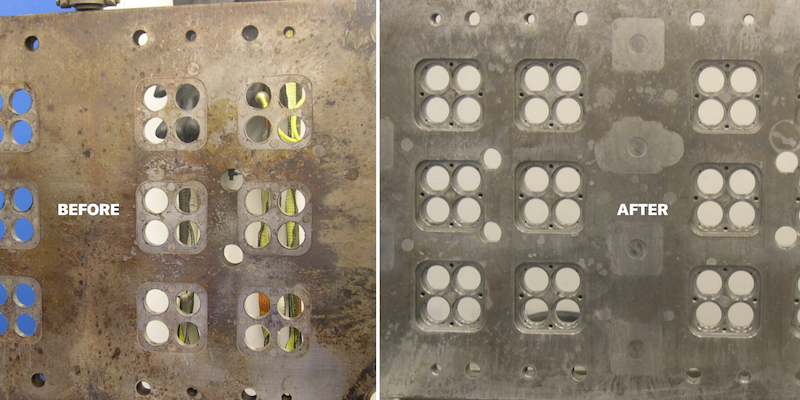

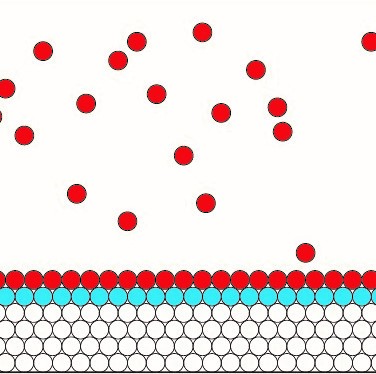

We see some interesting things with the injection molds that come across our plate. From parts sticking to galling, there are a lot of issues that can kill mold performance. The good news, surface coatings for injection molds can solve many of these issues. Let’s take a look at common Issues we use surface coatings …